Thanks to key business partners, the Concordia Community Mask Project is ramping up its N95-modeled mask production, taking its output from about 200 completed masks per week to around 1,000.

The result will be more PPE available for those in the community who need it. Individuals may request the N95-style masks here, and, thanks to a grant received from the Advancing a Healthier Wisconsin Endowment at the Medical College of Wisconsin, Concordia will facilitate the delivery of the masks to the users. The grant and donor contributions also cover the cost of materials and production. As a result, Concordia is able to offer the masks free of charge, while funds last.

Related: Concordia 3D-prints needed respirator masks amid COVID outbreak

There are essentially three steps involved in completing the N95-modeled masks that quickly became a direly needed resource amidst the Novel Coronavirus outbreak.

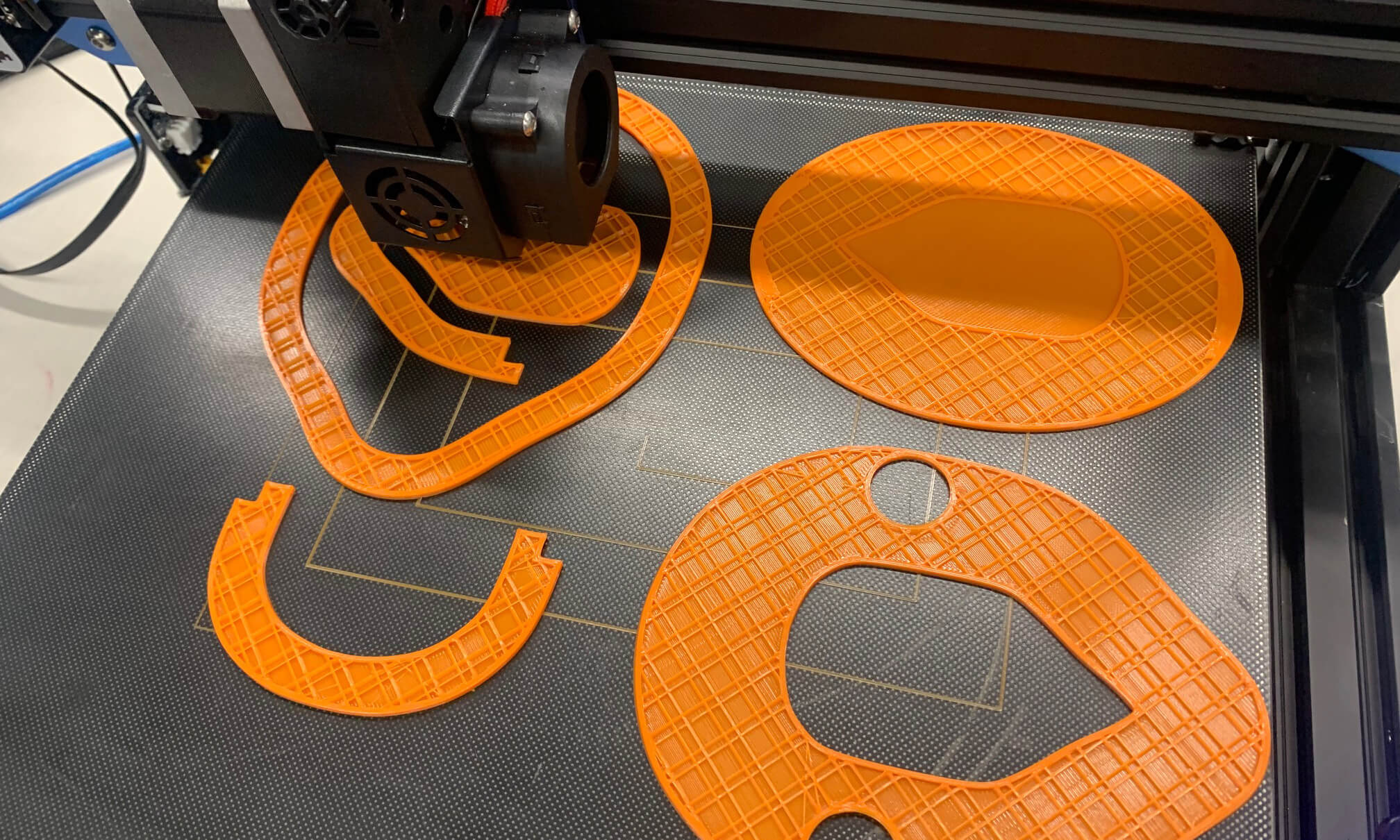

First, Concordia, along with dozens of community makers, 3D-prints the face piece. Concordia’s new Makerspace Lab hosts 82 3D printers, the largest printing capacity of any nonprofit in the state of Wisconsin. Next, a filter pack, intended to filter aerosolized virus, is inserted in the vented mouthpiece. Finally, a rubber gasket is applied to the perimeter of the mask to create a sealant between the device and the user’s face. This final step ensures sterility and blocks transfer of airborne germs.

Wisconsin businesses step up

Concordia recently solidified a partnership that sees Milwaukee-based rubber and plastics manufacturer Ritus Corp. mass-producing rubber gaskets for the masks. Previously, Concordia had recruited lay volunteers to manually pour the silicone gaskets. Under that model, the effort produced around 100-200 molds a week. Ritus estimates it will be able to produce around 250 per day.

Ritus isn’t the only Wisconsin business helping to boost the production of the needed protective gear.

Early on in the effort, Mr. Holland’s Heating and Air stepped in to offer filters and UV sterilization equipment for the project. When the demand outpaced the Jackson-based company’s scope, CEO and Founder Steve Holland pointed Concordia to Aprilaire, one of the largest suppliers of residential air purification filters and a subsidiary Research Products Corporation. Aprilaire quickly and generously agreed to partner with Concordia because of the philanthropic nature of the Concordia-led effort.

“As the leading nationally recognized brand of residential indoor healthy air products and solutions, Aprilaire is committed to doing its part, wherever possible, to lessen the impact of the COVID pandemic on our communities and our front-line workers. We are pleased to be part of the fantastic work being done by Concordia,” stated Mike McGowan, President and CEO of Research Products Corporation.

While Aprilaire provides the filters, Biocut Systems has stepped in to cut them at no cost.

“Biocut has basically provided the equivalent of a fulltime employee one or two days a week to cut these pieces and keep our production schedule humming,” said Concordia’s Batterman School of Business Dean Dr. Daniel Sem. “They’ve been cutting tens of thousands of filters for the effort for free each week. The whole Concordia Community Mask Project has been a tremendous and inspiring demonstration of a community rallying together for the good of each other in the midst of a scary and unprecedented period in history. That is why we call it the Community Mask!”

So far, over 500 masks have been provided to nursing homes, law enforcement, fire department, nurses, doctors, a dentist, politicians/election workers, a prison, funeral homes, ambulance drivers, and churches.

The Community Mask Project still needs community volunteers

Volunteers are still needed to assemble the filter packets and the masks themselves.

- Filter packet assembly is a simple task (it can be accomplished while watching television, for example) and can be done from the convenience of the volunteer’s home.

- Mask assembly must be performed at Concordia’s Innovation Campus in Wauwatosa, but also requires no expertise. Guidance and oversight is provided by a team of Concordia experts.

Learn more about how to volunteer here.

— This story is written by Kali Thiel, director of university communications for Concordia University Wisconsin and Ann Arbor. She may be reached at kali.thiel@cuw.edu or 262-243-2149.

If this story has inspired you, why not explore how you can help further Concordia's mission through giving.