The Concordia Community Mask Project continues its momentum as dozens of Milwaukee-area residents who volunteered for the effort begin to drop off their 3D-printed masks.

Nearly a month ago, Concordia began its effort to 3D print N95-modeled masks to be delivered to area professionals who are combating the novel coronavirus. Concordia is well-suited for the task since its brand-new Makerspace Lab boasts the largest 3D printing capacity of any nonprofit in the state of Wisconsin.

Nearly a month ago, Concordia began its effort to 3D print N95-modeled masks to be delivered to area professionals who are combating the novel coronavirus. Concordia is well-suited for the task since its brand-new Makerspace Lab boasts the largest 3D printing capacity of any nonprofit in the state of Wisconsin.

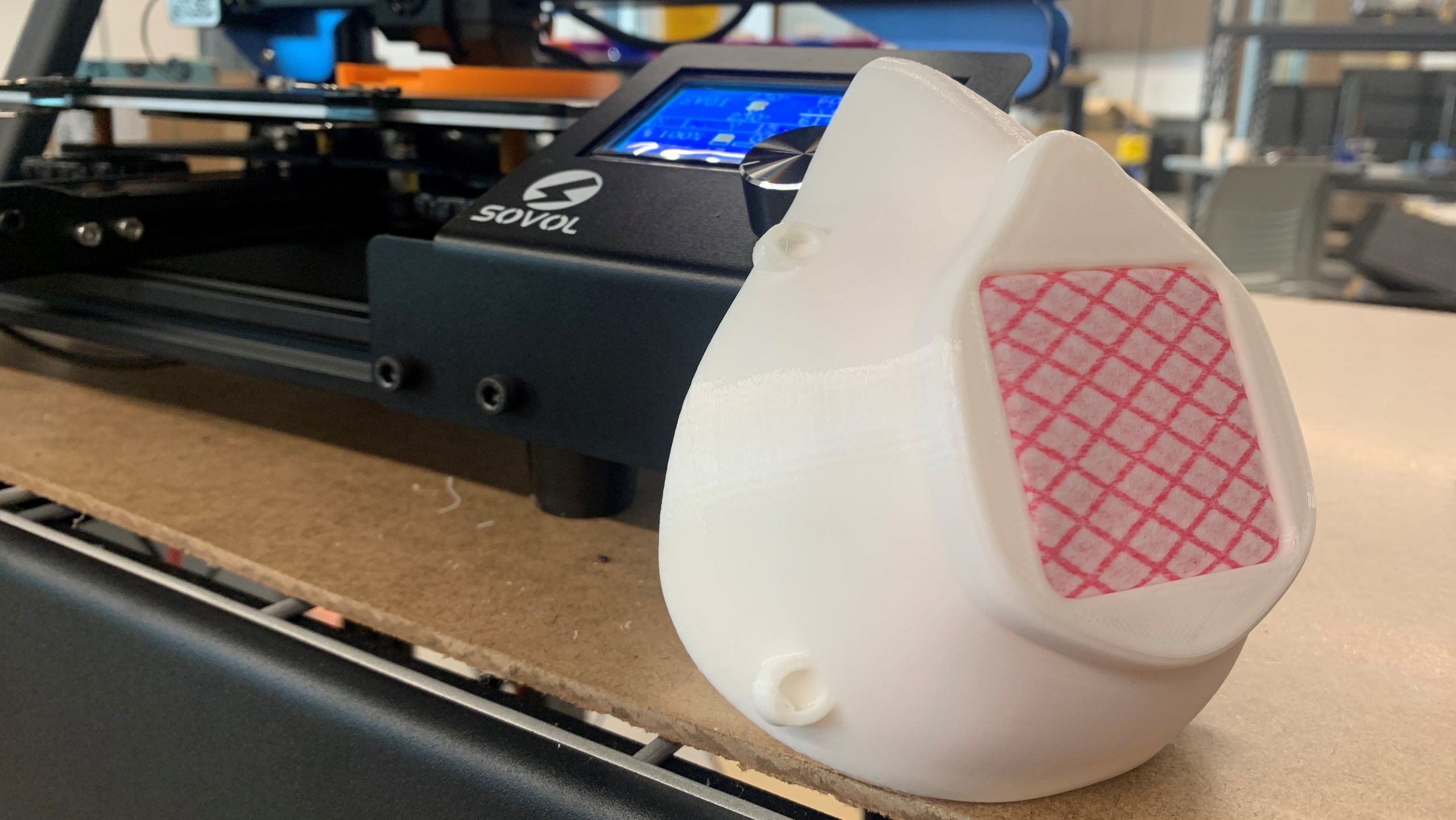

Spearheaded by Drs. Mike Litman (Computer Science) and Dan Sem, Concordia’s Batterman School of Business dean, the project saw Concordia team up with UWM’s Prototyping Center to identify an ideal prototype of an N95 mask to be printed. The universities are soliciting direct input from area medical experts on the front lines and have continued to modify the design based on feedback received.

Under the effort, Concordia asked anyone with 3D printers to register their machines so that they could contribute to the printing effort under the guidance of Concordia and its cohort. Community makers who drop off their masks at Concordia are also invited to pick up a spool of PLA, the material required for printing the masks, at no charge. Thanks to significant support from donors, along with a grant secured from the Advancing a Healthier Wisconsin Endowment at the Medical College of Wisconsin, Concordia is able to cover the cost of printing supplies and provide the masks free of charge to medical workers (until donated funds are depleted).

Nearly 140 Wisconsin residents and just under 40 out-of-state makers have registered their 3D printers. Last week, the first batch of community-printed masks was dropped off at Concordia’s campus. Several more drop-offs are anticipated this week.

“In total, from regional individuals, high schools, and colleges, I’d estimate that we’ve received over 200 3D-printed masks,” Litman said. “It truly is a community effort, which is why we’ve decided to call our prototype the ‘community’ mask.”

RELATED: WANT TO HELP THE CONCORDIA COMMUNITY MASK PROJECT? DONATE, VOLUNTEER, AND REQUEST PPE HERE.

To date, Concordia is responsible for printing about 500 masks. After an initial revision of the prototype, Concordia has arrived at a more finalized model. The design continues to be tweaked, however, to best-suit first responders’ needs.

“We’re working closely with the medical professionals who are using these masks and we’re doing all that we can to ensure they get what they need,” Sem said. “It’s an ongoing process. We’ll continue to modify our process until this pandemic is over.”

Under the current design, Concordia’s 30 3D printers can create up to 100 masks in 24 hours. The university began printing the most current prototype a little more than a week ago. Altogether, the machines have been working around the clock for nearly a month to arrive at the best model.

Under the current design, Concordia’s 30 3D printers can create up to 100 masks in 24 hours. The university began printing the most current prototype a little more than a week ago. Altogether, the machines have been working around the clock for nearly a month to arrive at the best model.

Once the masks are printed, they are delivered to the Innovation Campus, a research facility in Wauwatosa that Concordia shares with UWM. There, students from Concordia and UWM, as well as community volunteers, are working to add the final touches to the masks, including adding a silicone gasket, filters, and head straps. Then, the masks are distributed. The first batch of 65 masks was released two weeks ago, and another batch of 115 masks was released last week. The goal is to double production each week, until a target of at least 1,000 per week is reached.

Media coverage

Click on the images below to watch each station’s segment.

Concordia thanks its key community partners

Dozens of local businesses have stepped up to aid in the Concordia Community Mask effort by donating their supplies, resources, and dollars.

Thank you to the following companies and organizations:

- Husco International

- UWM

- Marquette

- Briggs & Stratton

- bb7 Product Development

- i3 Product Development

- Brooks Stevens Product Development

- Midwest Composite Technologies

- MasterGraphics

- Rexnord

- ProtoLabs

- Froedtert & MCW

- Children’s Hospital of WI

- New Berlin Plastics

- BioCut

- Milcut Inc.

- Quarels and Brady

- Savage Solutions

- Rockwell Automation

- AO Smith Foundation

- Quad Graphics

- RoddyMedical

- StrategX Solutions

More about Concordia’s grant funding

This project is funded in part by the Advancing a Healthier Wisconsin Endowment at the Medical College of Wisconsin.

The Advancing a Healthier Wisconsin Endowment (AHW) is a statewide health improvement philanthropy propelling promising work and ideas in health research, health care education, and community health initiatives to build a healthier Wisconsin today and for generations to come. Established by the Medical College of Wisconsin to steward a generous gift from Blue Cross & Blue Shield United of Wisconsin, AHW has invested more than $265 million in nearly 450 projects since 2004.

— This story is written by Kali Thiel, director of university communications for Concordia University Wisconsin and Ann Arbor. She may be reached at kali.thiel@cuw.edu or 262-243-2149.

If this story has inspired you, why not explore how you can help further Concordia's mission through giving.