Concordia University Wisconsin is putting its brand-new industrial engineering program and extensive 3D printer inventory to good use, collaborating with Penfield Children’s Center on a charitable project.

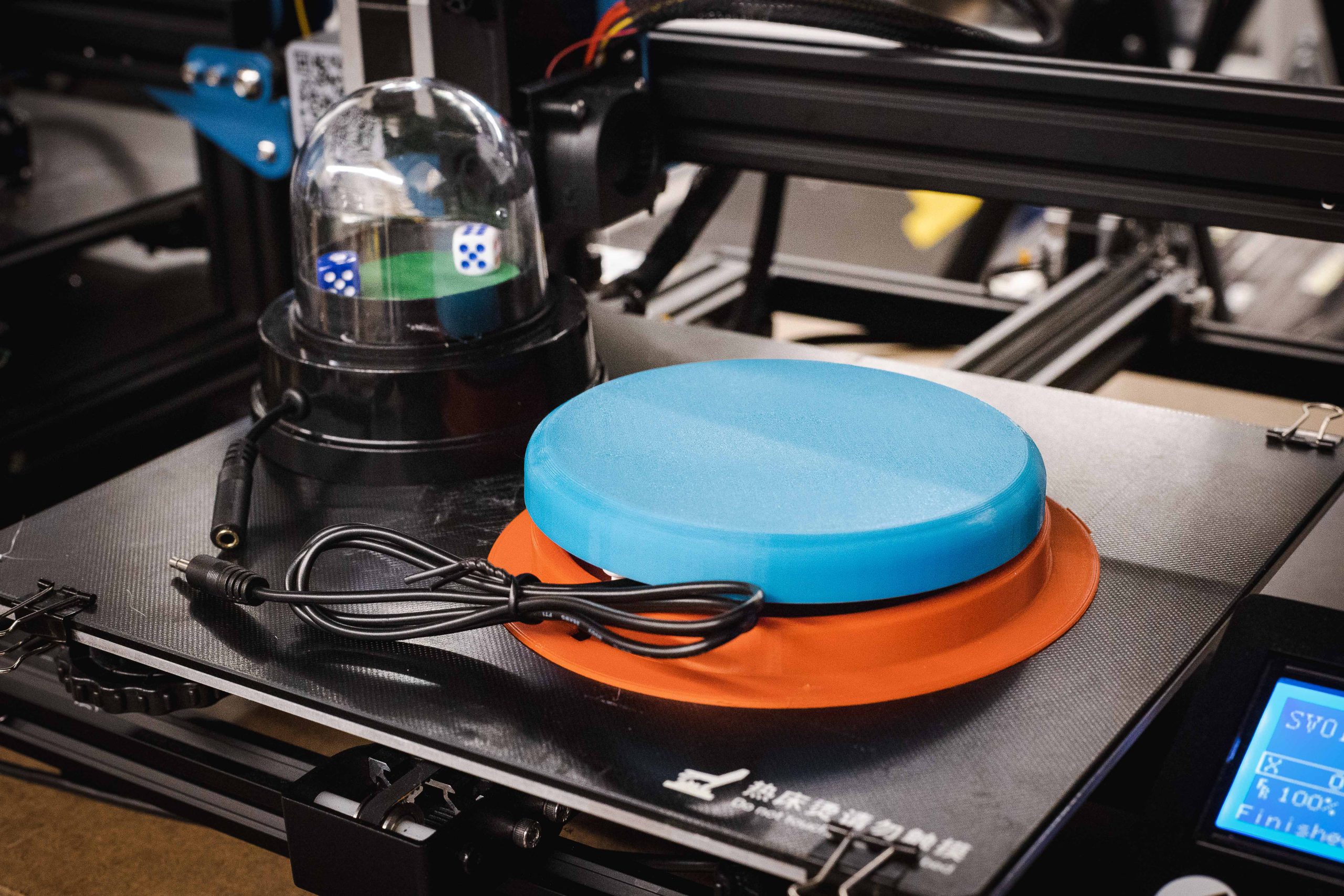

CUW engineering major Lucas Kearney recently helped to design an adaptive button for 3D printing within Concordia’s Makerspace. The button came at the request of Penfield Children’s Center, a nonprofit early education, health, and wellness center that offers services and family programming to more than 1,400 Milwaukee-area children annually. Penfield gifted the completed buttons to children attending their annual holiday party last Saturday.

What is an adaptive toy or device?

Adaptive toys or devices are every day items modified to accommodate a disability or fit a specific therapeutic need. The adaptive button that Kearney designed, for example, is a larger version of a tabletop push button that can be easily navigated by a child with disabilities or developmental delays. The button contains a connector that can then be plugged into an auxiliary jack to trigger a toy or device.

While adaptive toys have proven successful within the therapeutic realm, they often come with a hefty price tag. Vladimir Bjelic, a speech-language pathologist who works at Penfield, says an adaptive toy can cost anywhere from 200 percent to 300 percent more than a non-adaptive toy. Penfield has been able to reduce the price of the adaptive toys they use at their center by partnering with local school groups to have “build days.”

Concordia’s 3D printing contributions could help further reduce costs for Penfield in the future. The buttons CUW printed cost between $1-$6 per unit, compared to the $40-$100 cost Penfield had been paying. The buttons were the first venture between Concordia and Penfield. However, Bjelic says he is eager to explore more partnership opportunities in the future.

3D printing for therapeutic needs

Concordia’s Makerspace hosts the largest collection of 3D printers of any nonprofit organization in the state. As such, it has tremendous capacity to serve the community. In 2020, Concordia notably put its inventory to good use by printing much-needed PPE amid the coronavirus pandemic.

Since then, Assistant Professor of Computer Science Yiming Liao, who oversees the space, has expanded the lab’s applications. He has partnered with faculty from Concordia’s School of Health Professions to design and print other adaptive equipment for clients of the PT/OT Community Clinic, including an adaptive video game controller and an adaptive hair braiding tool.

Launching industrial engineering

Concordia announced last November its plans to launch two bachelor’s degrees in engineering. In July, the university hired Dr. Subha Kumpaty to helm the new programs. While the programs’ scheduled start isn’t until next fall, some students already decided to commit to the major.

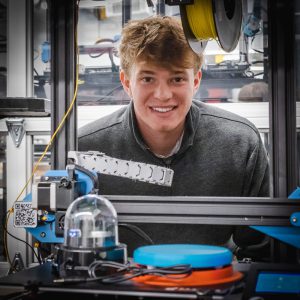

Kearney, who helped design the adaptive button for Penfield, is a freshman at CUW from Tinley Park, Illinois. As a high schooler, Kearney knew his eventual career track would involve something in the medical or engineering fields. When Concordia’s Head Baseball Coach Eddy Morgan recruited him to play for the Falcons, Kearney decided on CUW, even though the university didn’t have the full gamut of programs offerings he was weighing. Upon admission, he declared as a nursing major. However, he quickly switched once he learned about Concordia’s plans to launch the engineering programs.

“Thanks to Dr. Kumpaty, I’m already involved in a lot of opportunities, including an internship in the field,” Kearney said. “I’m super impressed by him. Not only does he have the brains to run a new program, but he has the expertise to understand the application of the subject in the real world.”

Want in?

Concordia University Wisconsin now offers bachelor’s degrees in chemical or industrial engineering. The programs will officially launch in fall 2024; however, applications are now being accepted for a pre-engineering track.

CUW’s engineering programs are distinct in the marketplace because they are anchored in the liberal arts and designed to prepare engineers through a Lutheran-Christian worldview. Students will hone their science, math, and technology skills for success in their vocation. And they will also deepen their people- and critical-thinking abilities to solve problems and contribute to a better world.